JGDE. Can you introduce us to Coriolis Composites, its markets, its prospects?

JGDE. Can you introduce us to Coriolis Composites, its markets, its prospects?

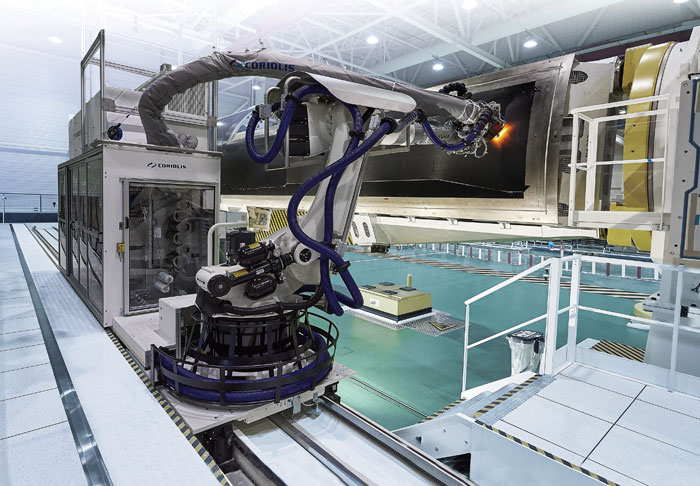

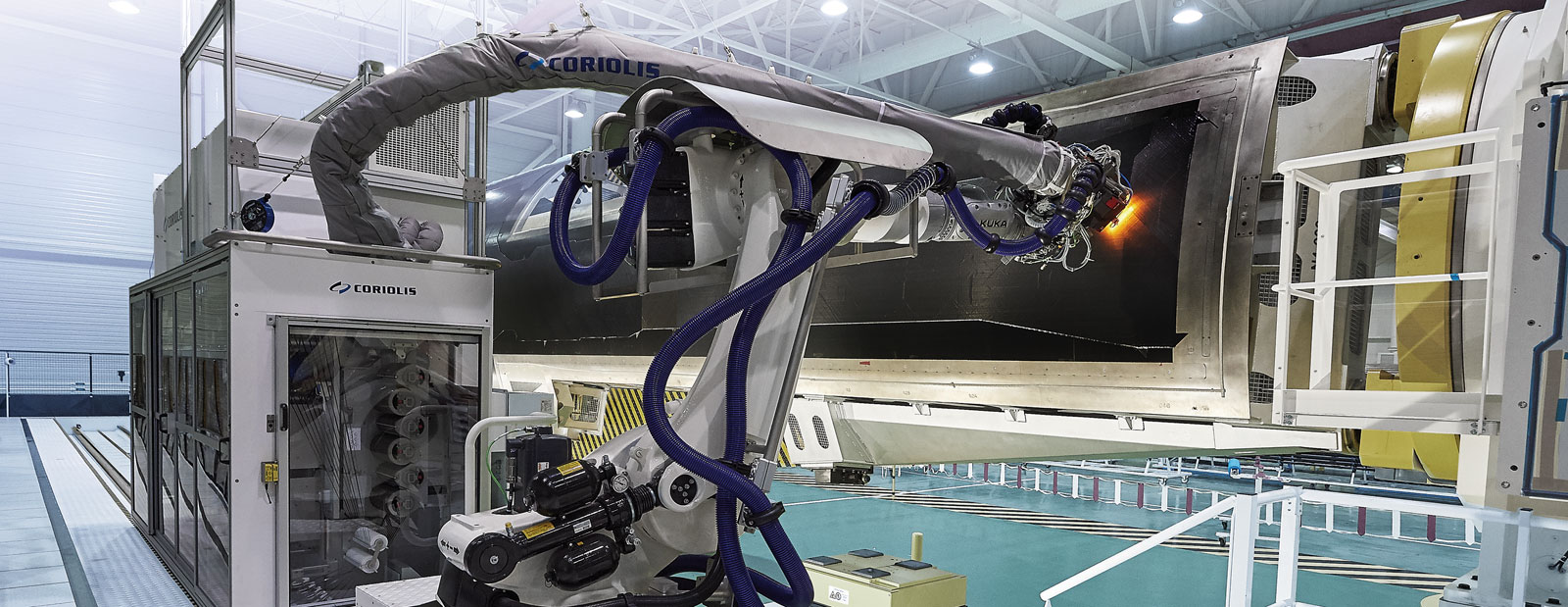

Clémentine Gallet. Coriolis was created in 2001 by three young engineers freshly out of school, who developed and marketed an innovative solution for manufacturing composite parts. Composite materials are used in the aerospace and transport sectors to reduce weight and limit fuel consumption. Coriolis has a turnover of € 27 million in the aeronautics and space market, 80% of which is exported. Coriolis robots are used in the factories of major aircraft manufacturers such as Airbus, Bombardier or Dassault Aviation, as well as by their subcontractors.

JGDE. Coriolis Composites is a company directly related to the precision industry. What answer do you give to the general vision of a deindustrialisation of France, and more particularly of the provinces?

CG. I see deindustrialisation as an opportunity to reconsider the foundations of our industry. We are experiencing a veritable transformation of our factories since the advent of digitalization and robotics. Using the latest generation of tools, it is once again possible to manufacture in France and remain competitive. We see it with the factories that we equip with our robots and which become more competitive thanks to this new equipment.

Our own development is proof of this: our added value lies in the innovative mechanical components and high performance simulation software that we develop. These technological building blocks are a direct product of French creativity and ingenuity. Our location in Lorient contributes to this technological and innovative success, as we offer young talents the “new generation” quality of life to which they aspire, where work, leisure and personal life are harmonised.

JGDE. You have just inaugurated the French Fab with the Minister of Economy, Mr. Bruno LE MAIRE. Can you explain what this project is about, and the involvement of Coriolis Composites in its implementation?

JGDE. You have just inaugurated the French Fab with the Minister of Economy, Mr. Bruno LE MAIRE. Can you explain what this project is about, and the involvement of Coriolis Composites in its implementation?

CG. I will paraphrase our Minister by saying that the French Fab provides a “showcase of our industrial, traditional and cutting-edge know-how” and gives a collective impetus to the “French-style industry of the future”. Naturally we are supporting this movement with 3 contributions: our history and technologies, our need for better representation as manufacturers in our future developments (including government support for innovation and export) and the challenges we face, that sometimes require advice from our ETI peers and fellow members of the French Fab.